Documents

Explore Aestech’s library of official documents, including international patents, classification and test reports, and construction specifications.

These resources showcase the performance, compliance, and innovation that underpin SkySheer's advanced glazing systems.

Discover how our technologies meet rigorous industry standards backed by thermal simulations and certified data.

Utility model patent

#DE 20 2021 101 714 U1

(57) Main Claim:

The light-transmitting enclosing structure, which includes insulating glass as one of its components where the glass panes are hermetically sealed and joined together with an internal rigid reinforcement profile and a spacer frame is characterized in that the insulating glass is additionally equipped with an external reinforcing U-profile, having a cross-section in the form of a GFRP (glass fiber reinforced plastic) pultrusion profile.

Utility model patent #144186

Application U 2020 062 63

Abstract (57):

The utility model relates to the field of construction materials, specifically to the production of light-transmitting enclosing structures of translucent materials. It can be used in industrial and civil construction, in facades of buildings and structures, as well as for replacing existing glazing systems and other light-transmitting elements.

The structure includes insulating glass where the glass panes are hermetically sealed, with an internal rigid reinforcing profile and a spacer frame securing them together. It is characterized in that the insulating glass is additionally equipped with an external U-profile having a cross-section in the form of a GFRP (glass fiber reinforced plastic) pultrusion profile.

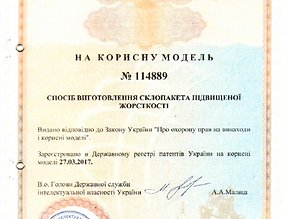

Utility model patent #114889

Application U 2016 099 19

Abstract (57):

The method for manufacturing a high-rigidity insulating glass unit includes two or more glass panes, which are hermetically sealed together using a special rotating jig. The panes are vertically placed at a distance of 2 to 30 mm. The inter-pane space is sealed along the entire perimeter of the unit by sequentially turning the special jig by 90 degrees. The insulating glass is assembled on a primary spacer frame, spaced at least 10 mm from the edge of the glass around the perimeter. The panes are filled with an adhesive mixture, embedded with a reinforcing profile, then cured for 15–20 minutes to harden. The procedure is repeated for each side of the unit.

Utility model patent #114888

Application U 2016 099 18

Abstract (57):

The high-rigidity insulating glass unit, intended as a translucent construction element for buildings, comprises two or more glass panes that are hermetically bonded together. It includes a rigid reinforcing profile firmly embedded between the glass panes along their edges, and optionally a perforated spacer frame that is rigidly connected to the reinforcing profile and bonded to the glass panes.

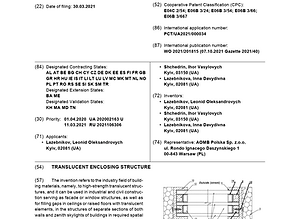

European Patent #4 130 420 A1

Application 21782040.6

(54) TRANSLUCENT ENCLOSING STRUCTURE

(57) The invention refers to the industry field of building materials, namely, to high-strength translucent structures, and it can be used in industrial and civil construction serving as facade or window structures, as well asfor filling gaps in ceilings or raised floors with translucent

elements, in the structures of separate sections of both walls and zenith skylights of buildings in required spatial altitude. The translucent enclosing structure comprises glass units wherein the sheets of glass are hermetically connected to each other and fixed relative to each other by an internal rigid strengthening profile and a spacer frame, and the glass units are additionally provided with an external strengthening profile of ∩-shaped cross-section in the form of a pultruded profile made of glass-plastic.

There has been created a sufficiently strong and, therefore, reliable, durable, and cheap translucent enclosing structure designed for use in industrial and civil buildings.

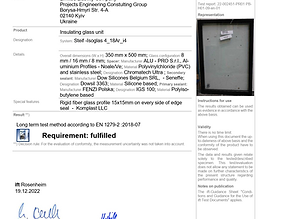

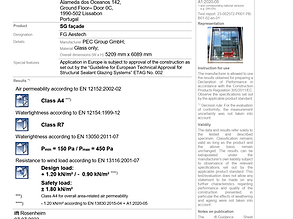

Classification Report 22-002451-PR01 (NW-H01-09-en-01)

Long term test method according to EN 1279-2 :2018-07

Requirement: fulfilled

EN 1279-2:2018-07 specifies a long-term test method for determining the moisture penetration index of insulating glass units (IGUs). It outlines the requirements for limit values and assesses the ability of IGUs to resist moisture intrusion over time

Classification Report 23-002572-PR01 (NW-B01-02-en-01)

Air permeability according to EN 12152:2002-02

Class A4

Watertightness according to EN 12154:1999-12

Class R7

Waterightness according to EN 13050:2011-07

Pmin = 150 Pa / Pmax = 450 Pa

Resistance to wind load according to EN 13116:2001-07

Design load: + 1.20 kN/m² / - 0.90 kN/m²

Safety load: ± 1.80 kN/m²

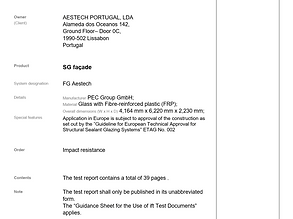

Impact ResistanceTest Report

22-003184-PR01 (PB-B01-03-en-01)

Product: SG façade

System designation: FG Aestech

Impact Resistance according to EN 14019:2016-06

Class: I5/E5

Details:

Manufacturer: PEC Group GmbH;

Material: Glass with Fibre-reinforced plastic (FRP);

Overall dimensions (W x H x D):

4,164 mm x 6,220 mm x 2,230 mm;

Impact ResistanceTest

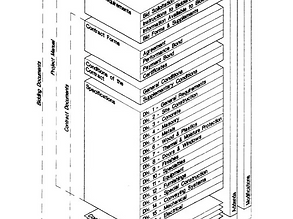

Specifications

SECTION 08 44 13

GLAZED CURTAIN WALL SYSTEMS (FRAMELESS)

SkySheer Frameless Glass Curtain Wall

by Aestech Engineering

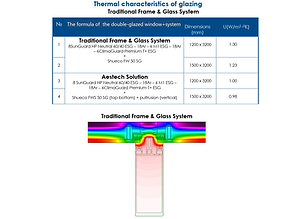

Thermal Simulation

The thermal analysis was carried out using the Window (v.6.3.74.0) + Therm (version 6.3.46.0) software package developed at the Lawrence Berkeley Laboratory (LBNL) at the University of California, USA.